Ever feel like you need a decoder ring to understand conversations about industrial cybersecurity? You’re not alone. The world of protecting the systems that run our critical infrastructure is swimming in acronyms – OT, ICS, SCADA, PLC, RTU – it’s enough to make anyone’s head spin!

The goal here isn’t just to throw definitions at you. We want to explore what these terms really mean, how they relate to each other, and why understanding them is crucial in today’s digitally transforming industrial landscape. We’ll even peek at how formal definitions, like those from NIST (National Institute of Standards and Technology), stack up against the more conversational explanations you might get from an AI like ChatGPT, giving us a “textbook vs. real-world” feel.

So, grab a coffee, and let’s demystify some of this essential jargon.

Operational Technology, or OT, is the backbone of the industrial world. It refers to the hardware and software systems that monitor and control physical processes, devices, and events. Think of it as the technology that makes things happen in the real world – from managing robots on an assembly line to controlling the flow of water through a treatment plant.

While it’s often associated with industrial control systems (ICS), OT’s reach extends to building management systems (like HVAC and security), medical devices, and more. It’s the umbrella term for the entire ecosystem that keeps these physical operations running.

Interestingly, ChatGPT emphasizes that OT is the overarching framework for other technologies like ICS and SCADA. It did initially narrow its focus to “industrial environments,” but as we know, OT’s scope is wider, covering non-industrial applications too. Point for the humans on that nuance!

But What About OT Security?

With great power comes great responsibility—and, unfortunately, some serious security headaches. OT systems were once isolated from the internet and the wild world of cyber threats. But as digital transformation and the convergence of IT (Information Technology) and OT have taken off, these systems are now deeply networked, bringing both efficiency and increased risk.

Cyber attackers have noticed. Now, threats like ransomware, malware, and unauthorized access aren’t just the stuff of IT nightmares—they’re real concerns for anyone running a factory floor, a water treatment facility, or even a hospital’s climate system. The consequences? We’re talking operational downtime, physical equipment damage, and even safety risks for workers and the surrounding community. In some cases, attacks on OT can have ripple effects that disrupt entire industries or regions.

Securing OT isn’t as simple as copying and pasting IT security solutions. The diversity of OT devices—everything from aging PLCs to modern, sensor-packed SCADA systems—means there’s no one-size-fits-all approach. Protecting these environments requires a mix of specialized technologies and practices: next-generation firewalls tailored for industrial protocols, robust access controls, and continuous monitoring that’s sensitive to how these systems operate in the real world.

The ultimate goal? Safeguard processes, people, and profit—while keeping those security vulnerabilities and incidents to a bare minimum. And as we’ll see, understanding the relationship between OT, ICS, SCADA, and other acronyms is key to building a meaningful security strategy.

You might be wondering, “Wait, if OT is the umbrella, where does ICS security fit into the picture?” Great question! Here’s the lowdown without the jargon overload:

OT Security is the big picture. It’s about protecting everything that monitors and controls the physical world—think robots, HVAC systems, pumps, medical scanners, and yes, all those industrial gadgets humming away in the background. If it moves, clicks, or manages real-world actions, OT security is there to keep it safe.

ICS Security, on the other hand, zooms in on the heart of industrial automation. It’s focused specifically on safeguarding industrial control systems: these are the command centers for manufacturing plants, power grids, water facilities, and more. ICS security aims to keep the critical “brains” of the operation safe from cyber threats, whether it’s a PLC, DCS, or SCADA system.

So, in summary: OT security is the security guard for the entire physical operation—from building management to medical tech—while ICS security is the elite force assigned to the main industrial controls. Both matter, but they’re not identical.

And speaking of ICS…

So, what happens when operational technology systems are compromised? The fallout isn’t just lost data or an inconvenient reboot—it can get a lot messier, fast.

Breaches in OT environments can ripple out in ways that impact:

In short, the risks go way beyond “IT headaches.” Breaches in OT systems can have genuine, tangible, and sometimes dangerous consequences both inside and outside the organization.

If OT is the umbrella, Industrial Control Systems (ICS) are a critical component sheltering underneath. ICS are the specific systems used to manage and automate industrial processes. This includes manufacturing, production, and distribution across various sectors.

NIST provides a couple of handy definitions:

ChatGPT aligns, stating that ICS are the “direct implementers of control and automation within the OT framework.” They are how OT achieves its goals.

A common question arises: If OT and ICS are different, what’s OT but not ICS? Good question! Think about building automation systems, medical devices, or even fire control systems. These are OT because they interact with the physical world via computer control, but they aren’t strictly “industrial control systems.” Even PLCs (we’ll get to those!) have applications beyond traditional ICS.

Now that we’ve teased apart the difference between OT and ICS, let’s tackle the next obvious question: how does security for OT differ from security for ICS?

OT security is the broad approach—it’s all about protecting the entire landscape of technology that manages, monitors, and controls real-world processes. That means ensuring the safety of not just industrial plants, but also hospital equipment, building automation, and beyond. The mission: keep people safe, processes efficient, and, yes, profits intact against ever-evolving cyber threats. As OT environments increasingly mingle with traditional IT networks (hello, smart factories!), the scope of “security” gets wider and more complex. Here, you’re protecting everything under the OT sun, whether or not it’s strictly involved in industrial production.

ICS security is more of a deep dive. Think of it as the “special operations team” focused on the specific systems that actually run industrial processes—manufacturing robots, refinery controls, power substation gear—you name it. Because ICS involves high-stakes automation and process control, a security slip could mean interrupted service, financial loss, or even safety hazards. Securing ICS isn’t just about strong passwords or firewalls; it’s about tailoring protections to each layer and component—PLCs, HMIs, sensors—so that the unique quirks and risks of each are covered.

In short:

Both are critical, but knowing where they overlap—and where they don’t—helps organizations prioritize the right protections for the right parts of their operation.

Now that we’ve got the lingo down, let’s tackle the million-dollar question: what sets apart OT security, ICS security, and SCADA security?

Think of it as layers of an onion, each with its own flavor and focus, but with plenty of overlap.

OT Security: This is the big-picture guardian, responsible for protecting all systems that monitor and control the physical world—not just those in heavy industry. OT security is about ensuring the availability, safety, and resilience of everything from HVACs in a skyscraper to medical devices in a hospital. Why does it matter? The increasing fusion of IT and OT has made these systems juicy targets for cyber troublemakers. The challenge: keeping these disparate technologies safe while still allowing them to communicate and innovate.

ICS Security: Narrow it down one layer, and you’re looking at security for the systems right at the heart of industrial processes—think the automation that keeps a power plant buzzing or a factory moving. ICS security involves protecting things like programmable logic controllers (PLCs), remote terminal units (RTUs), and the networks that tie them together. Here, the stakes are sky-high: a compromise could shut down production lines or even threaten public safety. Because ICS environments often run on legacy tech designed for reliability (not security), keeping them safe requires careful balancing—updating protections without breaking the mission-critical workflows.

SCADA Security: SCADA is the specialist in this family—the security focus is laser-sharp on systems that monitor and control operations across sprawling, often remote, environments. Picture the tech overseeing pipelines stretching across states or the grids that light up entire cities. The unique twist with SCADA? Its need for nearly real-time data and remote connectivity means extra vigilance—strong authentication, encrypted communications, robust incident response, and a keen awareness of what’s happening on the network every second.

In summary:

Each layer matters, and together, they form the fortress defending our digitized, physical world.

When we talk about ICS security, we’re diving into how we keep the nuts and bolts (sometimes literally) of industrial control systems safe, trustworthy, and humming along. This isn’t just about blocking hackers at the digital gates—it’s also about preserving the very machinery that keeps our factories, power plants, and infrastructures running day in and day out.

ICS security aims to protect several key components:

The functions ICS security focuses on include:

Ultimately, ICS security isn’t just a firewall or a locked door—it’s a comprehensive approach to defending both the brains and muscle of critical operations. It spans bits and bolts, ensuring the real world keeps turning safely and reliably.

Just as you wouldn’t leave the doors to a power plant wide open, ICS security is all about keeping the digital and physical gates firmly shut against troublemakers. In plain English, ICS security refers to the collection of strategies, technologies, and good old best practices aimed at protecting the specialized systems that run factories, power plants, water treatment facilities, and more.

Why does this matter? Because ICS is where the digital world shakes hands with the physical one: if a hacker gains access, they’re not just fiddling with spreadsheets—they could potentially stop production lines, disrupt energy supplies, or, in the worst case, cause real-world harm. That’s why ICS security is less about firewalls alone and more about making sure every piece—from programmable logic controllers (PLCs) and remote terminal units (RTUs) to human-machine interfaces (HMIs)—is defended from both cyber and physical threats.

The landscape has grown even trickier as industrial environments become more connected, with these systems now communicating over broader (and sometimes less predictable) networks. The goal of ICS security is twofold:

A slip-up in ICS security isn’t just about stolen data; it could mean halted operations or even risks to public safety. That’s why, whether you’re in power generation, manufacturing, or running the world’s fanciest HVAC system, treating ICS security as a top priority just makes sense.

Let’s talk real consequences. Breaches in Industrial Control System (ICS) environments aren’t just about stolen data or IT headaches—they hit where it really hurts: the physical world.

If attackers manage to penetrate ICS defenses, the fallout can be dramatic:

To guard against these risks, ICS security layers are both proactive (catching threats early) and reactive (ready to limit any damage). The entire system is built with the understanding that in ICS, the price of a breach isn’t just digital—it’s very real, and sometimes, very visible.

Within ICS, two major players are SCADA and DCS.

Supervisory Control and Data Acquisition (SCADA):

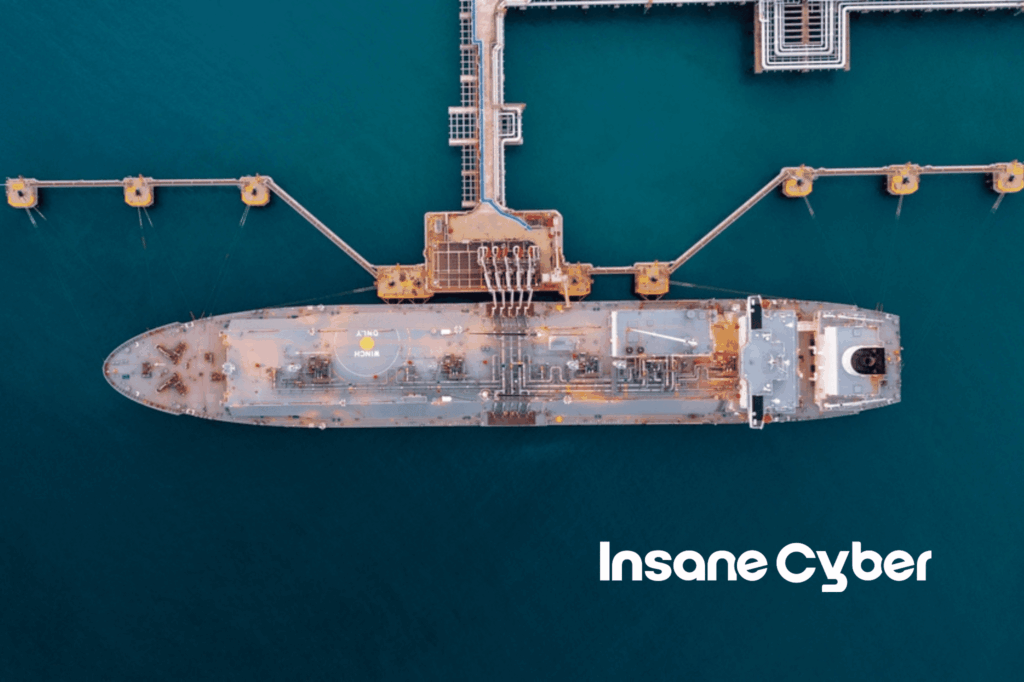

SCADA systems are considered a core component of OT, specifically used for real-time data collection and process control. They are designed for monitoring and controlling processes over large geographical areas. Think pipelines, power grids, or widespread water systems. Their strength is collecting data from remote locations and bringing it to a central point for analysis and control.

”

Let’s take a closer look at the security side of Supervisory Control and Data Acquisition (SCADA) systems. Since SCADA acts as the eyes, ears, and central nervous system for far-flung operations—think pipelines stretching for miles, sprawling power grids, or multi-county water supplies—keeping these systems secure isn’t just a nice-to-have; it’s foundational.

At its core, SCADA security means protecting the data, processes, and communication paths that these systems rely on. While their main job is to collect real-time data and automate control across remote assets, the trend toward open network architectures (hello, Ethernet and the internet!) has unfortunately broadened the attack surface. Suddenly, a misconfigured modem or outdated firmware isn’t just an IT headache—it could put a city’s water or power at risk.

So, what makes for robust SCADA security?

Why does this matter? The impacts of a SCADA breach go beyond lost data. We’re talking shutdowns at water treatment facilities, power blackouts, halted transportation—public safety is directly in the crosshairs. That’s why SCADA security isn’t just about IT hygiene; it’s about safeguarding essential services that millions rely on every day.

While “SCADA” tends to sound like a single flavor, there are actually three major generations you’ll encounter: Monolithic, Distributed, and Networked.

NIST and industry guides point out that while the tech has evolved, the core purpose—supervising and controlling complex operations—remains unchanged.

If you’ve ever wondered why the lights stay on, the water flows, and the trains run (mostly) on time, you’ve indirectly benefited from Supervisory Control and Data Acquisition (SCADA) systems. These unsung heroes quietly manage the vast, far-flung networks that underpin our most vital services: power grids, water supplies, transportation systems, and more. But with great responsibility comes great need for security.

Why Is SCADA Security So Crucial?

Because SCADA systems connect and control essential infrastructure over sprawling distances, they’re prime targets for cyber threats. Imagine a hacker flipping switches at a water treatment plant from halfway around the globe—that’s not science fiction, but a clear and present risk. The stakes are high: a compromised SCADA system could mean lights out for a city, unsafe water on tap, or stalled trains during rush hour. That’s not just an inconvenience; it’s a matter of public safety.

How Does SCADA Security Safeguard Us All?

The bottom line? Effective SCADA security isn’t just about protecting data or computer networks—it’s about safeguarding the services people rely on every day, and ensuring public safety in a world where digital and physical risks increasingly overlap.

The impacts of a SCADA breach extend well beyond just tampered data or hacked computers. Because SCADA systems manage essential infrastructure—think water treatment plants, power grids, or the regional rail network—even a small compromise can send big ripples through daily life.

Potential fallout includes:

In other words, the risks tied to SCADA aren’t confined to the digital world—they reach right into the physical fabric of society, putting both the economy and public wellbeing on the line.

So, what actually goes into securing SCADA systems? A robust SCADA security framework isn’t just about firewalls and fancy monitoring tools—it’s a multi-layered approach.

Here’s what you’ll typically find under the hood:

The goal? Stay a step ahead of evolving threats, while keeping SCADA systems reliable and processes running without a hitch.

But here’s the plot twist: the move toward open architectures and IP-based networks, while great for interoperability and flexibility, has created some notable headaches in the SCADA world—particularly on the security front.

Back in the day, SCADA systems relied on proprietary protocols and closed networks. That “security through obscurity” approach wasn’t perfect, but it did keep most opportunistic hackers at bay. Now, with many SCADA environments looking more like typical IT networks and using standard communications stacks (like TCP/IP), they’re no longer walled gardens.

What does that mean? The same vulnerabilities lurking in traditional IT—think ransomware, phishing, and unauthorized remote access—can now target SCADA infrastructures as well. The attack surface has widened, and so too has the importance of robust cybersecurity measures. These days, frameworks from organizations like NIST and ENISA stress layered defenses and continuous monitoring to help SCADA systems keep pace with evolving threats.”

2. Distributed Control Systems (DCS): In contrast to SCADA’s long-reach, DCS typically manage processes within a confined area, like a single plant or facility. They are common in complex process industries (think chemical plants or refineries) where high reliability and distributed control functions are key.

- **NIST (SP 800-82 Rev 2):** Defines control in a DCS as being “achieved by intelligence that is distributed about the process to be controlled, rather than by a centrally located single unit.”- **ChatGPT highlights:** DCS use in “complex process industries… where high-reliability control of various plant systems is required,” focusing on stability, efficiency, and safety within a localized plant.The key takeaway? SCADA for the big picture, geographically spread-out operations; DCS for complex, localized control.

This naturally brings up another nuanced point: when it comes to security, what sets SCADA security apart from ICS security?

Think of it this way—

So while ICS security is the umbrella—ensuring safe, resilient operations for all control systems—SCADA security is about making sure those long-distance nerve centers stay uncompromised, accurate, and online. Realistically, securing a refinery DCS and a national power SCADA brings wildly different threat models, requirements, and technical quirks to the table.

Just as ICS is the broader system, ICS security casts a wide net—covering every type of control system, from SCADA and DCS down to those ubiquitous PLCs and more. Think of ICS security as the guardian for all industrial automation environments, tasked with protecting the hardware, software, communications, and physical processes in play.

SCADA security, on the other hand, is a specialized subset zoomed in on the unique challenges of monitoring and controlling processes over distances. Because SCADA systems often span cities, regions, or whole countries (à la power grids or water treatment plants), the stakes for real-time protection and reliability are sky-high.

A few ways SCADA security stands apart:

In short: all SCADA security is ICS security, but not all ICS security is SCADA security. SCADA’s particular blend of real-time, distributed, and critical operations means it requires tailored protections alongside the wider security strategies applied to the full ICS landscape.

Let’s untangle this duo once and for all. While both OT and SCADA security aim to keep our critical infrastructure safe from digital threats, their areas of focus aren’t quite the same.

OT security is the broad guardian. It covers the entire spectrum of operational technology—including all systems that monitor or control physical processes. This means everything from building automation, conveyor belts, HVAC systems, to, yes, industrial control systems like SCADA, DCS, PLCs, and beyond.

SCADA security, on the other hand, zooms in on one specific (but highly important) type of ICS. Here, the focus is protecting the specialized systems that handle long-distance monitoring and control—think pipelines, electric grids, massive water treatment facilities. The emphasis? Securing remote communications, real-time data acquisition, and the unique vulnerabilities of widely dispersed assets.

So, you can think of OT security as the big umbrella, while SCADA security is one essential rib—laser-focused on the risks and challenges that come with sprawling, often geographically dispersed operations.

At the very heart of many industrial automation setups are Programmable Logic Controllers (PLCs). These are essentially ruggedized industrial computers designed to withstand harsh environments. PLCs are the direct hands-on controllers of machinery and processes, taking inputs from sensors and executing outputs based on their programming.

Think of PLCs as the Lego blocks of industrial automation. They receive data, process it according to their programmed logic (often “ladder logic”), and then tell machines what to do – open a valve, start a motor, move a robotic arm. They are fundamental to both SCADA and DCS environments.

Remote Terminal Units (RTUs) are crucial for extending the reach of SCADA systems. These devices are deployed in the field to collect data from sensors and transmit it back to a central SCADA master station, as well as execute control commands sent from that master.

While PLCs focus on local process control, RTUs are optimized for remote data acquisition and control. Sometimes, a PLC might be configured to act as an RTU, blurring the lines a bit. NIST groups RTUs under both DCS and SCADA, but their prominent role in geographically dispersed SCADA systems is undeniable.

You’ll often hear “HMI” and “EWS,” and while they both involve human interaction with control systems, they serve different purposes.

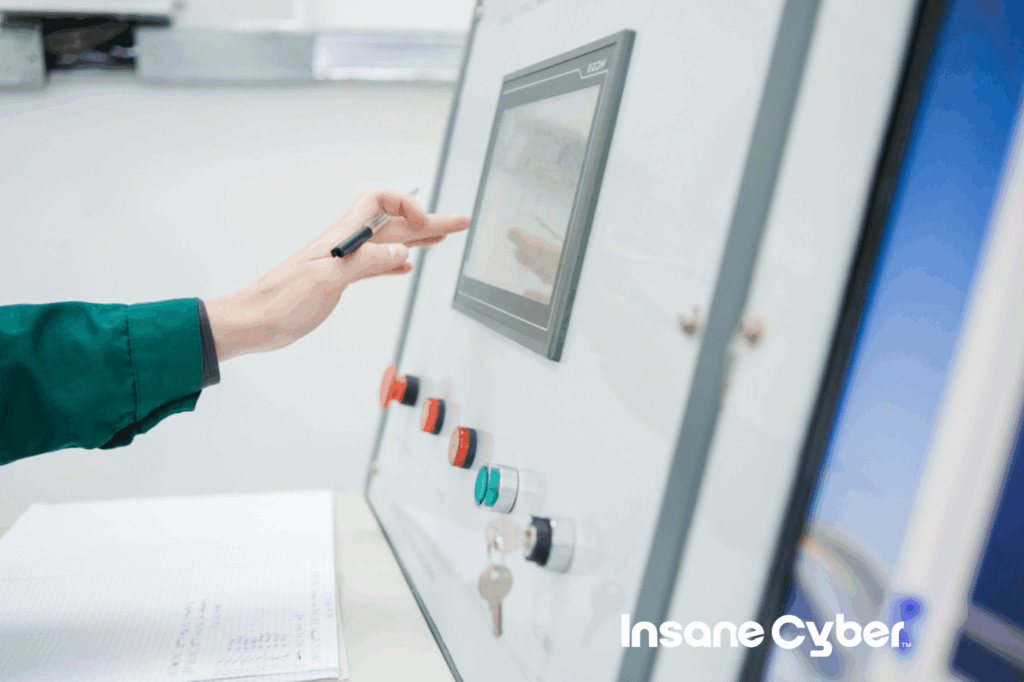

Human Machine Interface (HMI): The HMI is the operator’s dashboard. It’s the hardware or software that allows a person to interact with the control system – to monitor what’s happening, see visualizations (like system schematics or production trends), and make operational adjustments.

The controller itself (like a PLC) usually doesn’t have a screen and keyboard directly attached; the HMI provides that window.

Engineering Workstation (EWS): An Engineering Workstation is a more specialized tool. It’s used by engineers and system integrators for in-depth system configuration, programming (like writing PLC logic), diagnostics, and making significant changes to the control system.

So, think HMI for day-to-day operations and monitoring, and EWS for the heavy lifting of programming, configuration, and advanced troubleshooting.

Navigating the Challenges of Digital Transformation & IoT Security in Industrial Environments

Understanding these terms is especially critical as industries charge ahead with digital transformation. Connecting previously isolated OT systems to corporate networks and the internet brings immense benefits, but also new cybersecurity headaches.

Common Roadblocks:

The Expanding Scope of OT, ICS, and SCADA Security

As digital transformation accelerates, it’s important to recognize that operational technology (OT) security isn’t just about network firewalls or passwords. OT security involves safeguarding the industrial systems—the very backbone of critical infrastructure like power plants, water treatment facilities, and manufacturing lines—from cyber threats. These environments rely on specialized hardware and software to control machinery and physical processes, and a security breach can lead to operational downtime, physical damage, and even put people and communities at risk.

The convergence of IT and OT networks has been a game changer. Once isolated, OT systems are now tied into broader corporate and even cloud networks. While this empowers efficiency and automation, it also exposes these systems to new vulnerabilities like malware, ransomware, and unauthorized access. The diversity of OT assets—ranging from distributed control systems (DCS) to supervisory control and data acquisition (SCADA) platforms—adds to the complexity. Each piece, from PLCs to HMIs, requires specific and sometimes creative security measures to minimize risk.

Effective OT security means more than digital protections. It encompasses practices and technologies that protect not just information, but also the physical safety and continuity of operations. This includes next-generation firewalls, security information and event management systems, access controls, and rigorous monitoring. The aim: comprehensive visibility and tailored security policies that cover the unique requirements of industrial environments, ensuring that processes, people, and profits are protected at all times.

ICS and SCADA: The Heart of Industrial Security

Industrial Control Systems (ICS) are at the core of managing and automating industrial processes. Their security is fundamental—not just for data integrity, but for the safety and reliability of the machinery and the environment. With the rise of networking, each ICS component—whether a PLC, HMI, or RTU—demands robust protection to prevent unauthorized access, data breaches, and operational malfunctions. ICS security is a blend of preventive and responsive measures, aimed at identifying threats early and responding quickly to mitigate damage.

SCADA systems, which oversee and automate large-scale, geographically dispersed operations, are particularly sensitive. Their adoption of open architectures and IP-based communications creates both opportunity and risk. A breach here could disrupt energy grids, water supplies, or transportation networks, with consequences that extend far beyond digital damages to touch public safety and essential services.

Best practices for SCADA security include layered controls—think governance, risk management, compliance, and technical safeguards—plus close collaboration with vendors, who are often responsible for developing and maintaining these critical systems. By reinforcing every layer, organizations ensure resilience against evolving and sophisticated cyber threats.

The IoT Identity Crisis

The explosion of Internet of Things (IoT) devices—including Industrial IoT (IIoT) sensors and actuators in OT environments, and Internet of Medical Things (IoMT) devices—creates a massive identity management challenge.

Key Identity Hurdles for Connected Devices:

Practical Solutions for IoT/IIoT/IoMT Identity:

Successfully navigating these challenges requires a blend of smart strategy, the right technology, and a commitment to continuous adaptation.

So, how do all these terms and challenges fit into a cohesive cybersecurity strategy? They form the very foundation. Effective industrial cybersecurity isn’t about a single fix; it’s a holistic approach that safeguards networks, infrastructure, hardware, software, applications, and data as a unified whole.

Think of it like defending a medieval castle. You need strong outer walls (network security), guarded gates (access control), secure towers (endpoint protection for PLCs, RTUs, HMIs), and protection for the crown jewels within (data security).

This layered defense, often guided by frameworks like the NIST Cybersecurity Framework, is essential. It means evaluating every component of your OT environment—from the individual PLC to the overarching SCADA system—and shoring up defenses against both external and internal threats. By weaving these layers together, organizations can better prevent, detect, respond to, and recover from cyber incidents, keeping critical operations safe and sound.

By looking at definitions from sources like NIST and the broader understanding reflected by AI tools, we see the value in both. NIST provides the rigorously vetted, community-agreed-upon foundation. AI, drawing from a vast dataset, often reflects how these terms are practically understood and used in everyday conversation.

In the dynamic and vital field of industrial cybersecurity, clarity is king. Understanding the official definitions while appreciating colloquial interpretations helps us all communicate more effectively and uphold the security standards protecting our essential infrastructure.

We hope this tour through the landscape of industrial cybersecurity terms has been enlightening! Grasping this vocabulary is the first step to building a more secure industrial world.

Our products are designed to work with

you and keep your network protected.