The lines between Information Technology (IT) and Operational Technology (OT) are blurring fast. As industrial systems—from power plants and pipelines to water facilities and manufacturing lines—become increasingly connected, IT professionals are being called to secure unfamiliar territory.

But here’s the catch: what works in IT doesn’t always translate to OT. In fact, applying traditional IT security strategies without adjusting for OT realities can backfire—halting operations, damaging equipment, or even putting lives at risk.

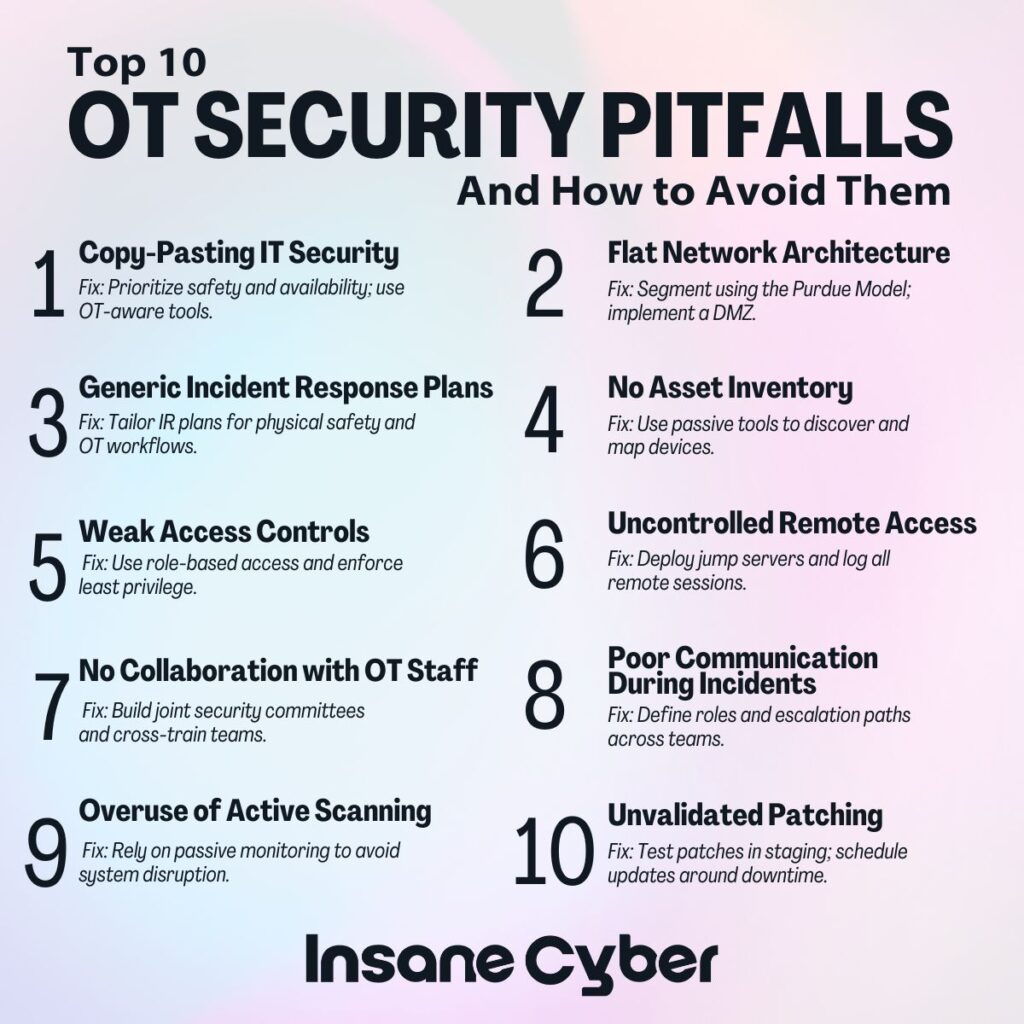

To secure OT environments effectively, IT teams must rethink their approach. Below are five of the most common mistakes they make—and how to steer clear of them.

Mistake 1: Copy-Pasting the IT Playbook

In IT, the security triad is confidentiality, integrity, and availability (CIA)—in that order. But OT flips that model. In industrial settings, safety comes first, followed by availability, then integrity. Confidentiality? Often a distant fourth.

So, when an IT team rolls out aggressive vulnerability scans or automatic patch updates in a factory or power station, it’s not just ineffective—it can be dangerous. A seemingly harmless auto-reboot could shut down critical operations, damage hardware, or create a safety hazard.

How to Fix It: Adapt, Don’t Adopt

Collaborate Early: Don’t implement changes without input from OT engineers who understand the operational impact.

Assess with Safety in Mind: Conduct joint risk assessments that prioritize uptime and safety.

Use Industrial-Grade Tools: Choose solutions designed for OT environments—ones that rely on passive monitoring rather than active probing.

Patch Smartly: Schedule patches during planned downtime, and always test in a staging environment first.

Mistake 2: Flying Blind Without Asset Visibility

You can’t defend what you don’t know exists. And in OT, you’re likely dealing with a mix of legacy systems, proprietary protocols, and undocumented devices tucked behind closed panels—often running mission-critical tasks.

Without a clear, current inventory of all assets, security gaps go unnoticed, and threat detection becomes a guessing game.

How to Fix It: Illuminate the Landscape

Build a Real-Time Asset Inventory: Use passive network monitoring tools to discover and fingerprint everything from PLCs and RTUs to HMIs and industrial switches.

Understand Traffic Flows: Map how devices communicate. Establishing a behavioral baseline makes it easier to spot anomalies—like a PLC suddenly reaching out to the internet.

Keep the Inventory Updated: Industrial networks change slowly, but even minor updates can introduce new risks. Review the inventory regularly.

Mistake 3: Overlooking the Human Factor

IT staff bring cybersecurity expertise, but OT professionals hold deep domain knowledge. A common mistake? Implementing security policies without consulting the folks who operate and maintain the systems.

This top-down approach can lead to workarounds, operational disruptions, and distrust—eroding the very security posture you’re trying to improve.

How to Fix It: Build Trust Across the Aisle

Create Joint Cyber Committees: Involve both IT and OT in every stage of the security planning process.

Invest in Cross-Training: Send IT staff to the plant floor and offer tailored cybersecurity training to OT personnel. Shared context builds cooperation.

Clarify Communication Channels: Ensure both teams know exactly who to contact when incidents arise. Roles should be clearly defined and documented.

Mistake 4: Keeping a Flat, Unsegmented Network

Historically, many OT systems were “air-gapped”—completely disconnected from IT. But those days are gone. With the rise of remote access, cloud dashboards, and predictive analytics, interconnectivity is now the norm.

The problem? Many environments still rely on flat network architectures, which means malware or threat actors that compromise IT systems can move laterally into OT—often undetected.

How to Fix It: Segment and Safeguard

Implement the Purdue Model: Divide the network into tiers, separating enterprise IT, control systems, and field devices.

Create a DMZ: Introduce a demilitarized zone between IT and OT networks. Inspect and tightly control all traffic moving between zones.

Restrict Lateral Movement: Use firewalls, VLANs, and strict access control lists to ensure only essential communication occurs across segments.

Mistake 5: Using a Generic IT Incident Response Plan

In IT, incident response often focuses on preserving data and restoring systems. In OT, the stakes are different. It’s not just about uptime—it’s about safety, physical processes, and human impact.

An IT-centric playbook that overlooks OT realities can delay response times or trigger unsafe shutdowns. Worse, it can sideline the very people who know how to safely stop a runaway process.

How to Fix It: Create an OT-Centric IR Plan

Involve OT Operators in Planning: Work with plant managers and engineers to write response playbooks tailored to industrial risks—like HMI lockouts, PLC infections, or SCADA disruptions.

Assign the Right Authority: Make sure the people who truly understand the systems have the authority to act during an incident.

Run Drills That Reflect Reality: Tabletop exercises should include real-world OT scenarios and both IT and OT participants.

Final Thoughts: Secure Together, or Not at All

Bridging the IT/OT divide isn’t just a technical challenge—it’s a cultural one. Security in industrial environments demands humility, cross-disciplinary respect, and tools that are purpose-built for the job.

The good news? When IT and OT teams work together, they can create a security program that’s not only resilient, but deeply aligned with operational priorities. The result is safer, more reliable critical infrastructure—and fewer surprises on the factory floor.

Need Help Securing Your OT Environment?

If your IT team is stepping into OT territory, you’re not alone—and you don’t have to go it alone. Our experts specialize in helping organizations bridge the IT/OT gap without compromising safety, uptime, or visibility. Let’s work together to uncover risks, implement practical defenses, and build a cyber-resilient future for your operations.

Contact us today to start the conversation.